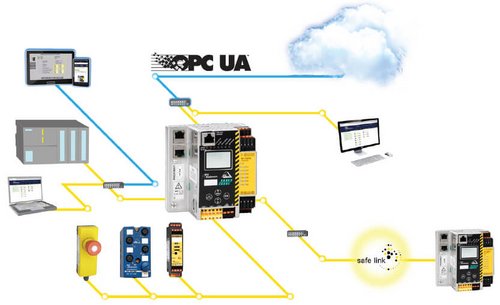

OPC UA – universal data exchange with the cloud

The digital networking of industrial production with information technology is the central nervous system of the intelligent factory of tomorrow. With a new hardware platform Bihl+Wiedemann is ensuring that the data from actuators and sensors arrives with optimal preparation at the top IT level. The bridge between the worlds leads first over the open communication protocol OPC UA, which has established itself currently as the first de facto standard for industry 4.0 applications.

Video length: 1:07

Universal data exchange – from sensor to the cloud

OPC UA provides direct data exchange for all connected devices – regardless of the fieldbus.

OPC UA – data exchange standard for Industry 4.0

- Industry 4.0 requires consistent, standardized communication

- OPC UA is the platform-neutral data exchange standard for direct vertical transmission of process, status and diagnostics functions

- Structured data even without programming

- OPC UA simplifies Machine-to-Machine (M2M) communication

- Simple incorporation into Industrial Internet of Things (IIoT) networks

Data connected from sensors and actuators via AS-Interface (ASi) are not only indispensable for the controller. Higher levels, such as diagnostics programs, remote maintenance servers, visualization systems and cloud-based applications require reliable data from the lowest field level. This means it makes sense to transfer "raw", i.e. unprocessed data from the machine.

OPC UA offers you the following advantages:

- Universal data exchange across all automation levels

- Networking of machine parts or entire plants is possible

- Your data in any number of systems, i.e. in a smartphone or the cloud

- Simple connection to common ERP and cloud solutions such as SAP and Microsoft Azure

Possible OPC UA applications

- Easy to perform diagnostics across all levels – without detours through the fieldbus; a comprehensive solution from the actuator and sensor level, control level, production control (MES) level, manufacturing and execution level all the way to corporate planning

- Remote maintenance

- Data analysis in the cloud – such as detection and automatic correction of tool wear and discovering process irregularities

- Big Data made usable through intelligent algorithms – such as analyzing tools from various manufacturers; comparing the respective service life and costs

- Representation and analysis on any kind of media – such as Human Machine Interface (HMI), tablet and smartphone

- Early scheduling of service deployments (predictive maintenance)

- Consistency of the data over the entire product life cycle

- Integration of vendors and information exchange with the customer

The advantages of OPC UA solutions from Bihl+Wiedemann

ASi gateways from Bihl+Wiedemann are often the first component in the automation pyramid that provides sufficient performance for delivering all the data from actuators and sensors to different interfaces.

You can call up the accumulated data in a cloud to a local server or to a visualization tool.

- One data exchange standard for all machine and system parts, which means no merging and no conversion of data necessary

- Universal, horizontal integration – from diagnostics on an HMI to networking of different plants around the world

- Relieves the fieldbus

- Certificate-based security integrated

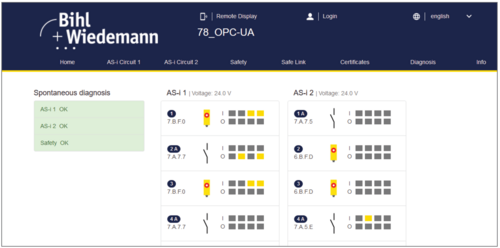

Web server in gateways from Bihl+Wiedemann

The new web server from Bihl+Wiedemann has universal application – regardless of the display medium (smartphone, tablet or PC) and the fieldbus. The fast, secure Web server stands out with its simple operation.