Single Pair Ethernet and ASi-5 – when and where does which technology make sense?

What is Single Pair Ethernet?

Single Pair Ethernet (SPE) enables the transmission of data via Ethernet with just one twisted pair of wires. Transfer rates of 10 MB/s to 1 GB/s are currently possible. In contrast, the previous Ethernet technology used in industrial applications requires two or four cable pairs. The two-wire design of Single Pair Ethernet therefore reduces the cabling weight by almost half compared to conventional categories of Ethernet cables.

Furthermore, SPE is used to standardize power transmission. Through Power over Dataline (PoDL), both power and data with an output of up to 50 W are transported on a cable, which are not compatible with the current Power over Ethernet standard.

The idea to develop SPE technology came from the automotive industry. That's because wiring accounts for a large part of the vehicle's weight. In industrial applications, Ethernet with SPE is intended to close the gap between the control system level and the field level, i.e., the sensor/actuator networks, and to create a consistent Ethernet connection. For this reason, SPE cables and connectors are significantly smaller, lighter, and easier to install than previous industrial Ethernet solutions, and ASi needs no connectors at all.

Content

- What is Single Pair Ethernet?

- Conclusion: Single Pair Ethernet and ASi-5

- FAQs about Single Pair Ethernet

- ASi Cable = extremely simple installation + efficient power distribution

- Technical comparison – ASi-5 vs. Single Pair Ethernet

- Switch instead of protocol converter

- Communicative break between ASi-5 and TCP/IP increases cybersecurity

- ASi-5 eliminates the need for connectors

- What is Ethernet-APL?

- SPE is developed by several groups

What is Ethernet-APL?

Ethernet-APL (Advanced Physical Layer) is a technology that was developed primarily for its use in the process industry. In order to access field data via IIoT, interfaces that are compatible with Ethernet are required in the process industry. Ethernet-APL is a special definition of Single Pair Ethernet, which is based on 10Base-T1L and is connected via screw or spring-type terminals.

Robustness, simplicity and explosion protection - High requirements of the process industry are met

The Ethernet-Advanced Physical Layer (Ethernet-APL), which is based on Single-Pair Ethernet (SPE), meets the high requirements of the process industry in terms of robustness, simplicity and explosion protection. With Ethernet-APL, data can be transmitted over longer distances of up to 1,000 meters, even under extreme temperatures and harsh environmental conditions. Ethernet-APL is capable of transmitting data at a rate of 10 Mbps with a power supply over two wire lines, making it a cost-effective solution for the process industry. When Ethernet-APL is used in process automation, it can enable seamless integration, monitoring and control of production processes and installations in real time.

The cables and terminals used in Ethernet APL technology are certified according to the explosion protection standard and meet the safety requirements in potentially explosive areas.

SPE is developed by several groups

The SPE technology is being developed by different associations for a variety of applications.

Each association has a different focus of work and partners or members from different industries. The following three associations are particularly important in this respect:

- Single Pair Ethernet System Alliance

It is an association of companies committed to the dissemination and development of Single Pair Ethernet solutions. Members work together to raise awareness of the advantages of Single Pair Ethernet in various applications and to promote the diffusion of SPE solutions. The activities of the SPE System Alliance focus on the entire future SPE ecosystem and not on a specific connector system or product.

- Single Pair Ethernet Industrial Partner Network

Founded by seven technology leaders in 2019, the SPE Industrial Partner Network consists of more than 50 member companies. It is an alliance of equal companies pushing Single Pair Ethernet technology as the foundation for rapid growth of the IIoT. The goal of the network is to establish SPE as a new Ethernet technology on the market in the sense of a comprehensive ecosystem with all necessary components.

- Single Pair Ethernet Consortium (SPEC)

The SPEC is a manufacturer-neutral organization for technology leaders and users in the field of building automation technology. One of the consortium's goals is to accelerate the introduction of Single Pair Ethernet in building automation technology and to push the implementation of flexible, cost-effective and reliable network solutions. The production of case studies, white papers, and reference architectures, as well as collaborative partnerships with other SPE initiatives and organizations, are also among the SPEC's goals.

Different connector types and standard sections

All associations use different connector types and standard sections that are optimized according to the requirements of the respective industry and application and are often not compatible with each other. A standardization guideline applicable to all that would ensure compatibility of the various devices and systems does not yet exist. Although there are efforts to promote standardization of connectors for SPE solutions, but so far, there is still no solution.

ASi-5 eliminates the need for connectors

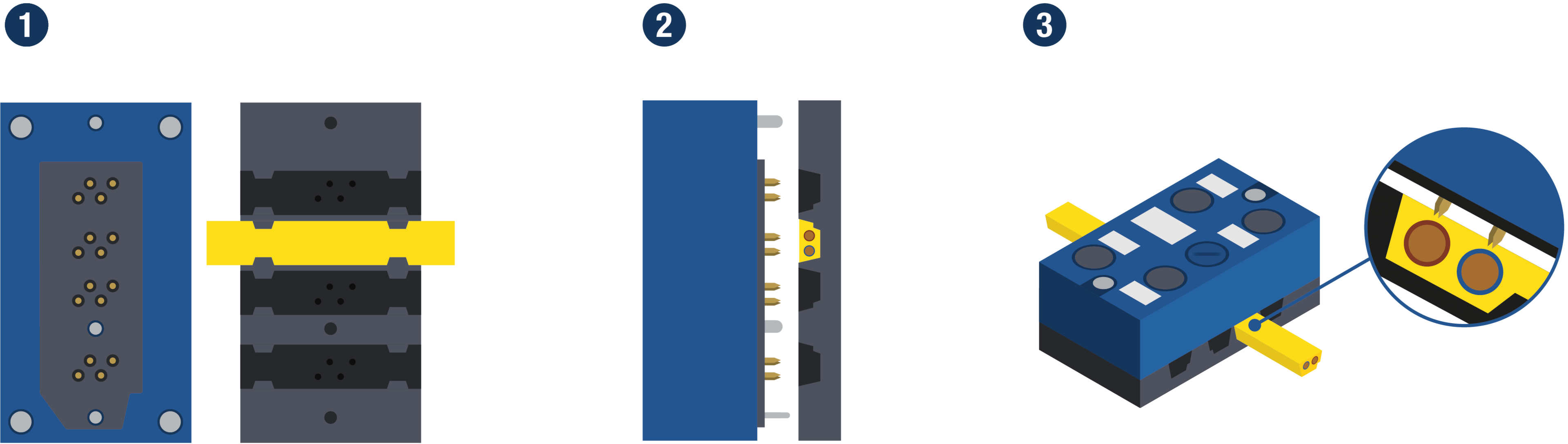

ASi connects sensors and actuators with a controller via a single two-core profile cable. The yellow ASi cable transmits power and data at the same time, with a power rating of up to 240 W. Today, the latest ASi generation is already conveniently and cost-effectively replacing many conventional Ethernet connections in the field. Besides the lower costs of ASi, its greatest advantage is that penetration technology makes it possible to completely eliminate the need for prefabricated cables and connectors.

What's more, ASi-5 is a completely redesigned system that is optimally adapted to the requirements of Industry 4.0. Thanks to the high data size and short cycle times, which are more than sufficient for many Ethernet-based automation solutions, many things that were previously impossible with AS-Interface can now be realized.

For this reason, ASi-5 is already being used to replace conventional Ethernet connections cost-effectively and conveniently. We offer a wide range of solutions for this. Here are three examples:

- Our ASi-5 Motor Module for SEW MOVIMOT® (BWU4068) enables the same data image as with an optionally available PROFINET interface from the manufacturer.

- The ASi-5 Motor Modules for Interroll EC5000 AI (BWU4246, BWU4212) offer the same drive control data as the manufacturer's Ethernet-based roller controllers.

- With our ASi-5 IO-Link Masters (e.g., BWU4067, BWU3819), you can save up to 40% on a medium-sized application with 50 IO-Link devices compared to comparable Ethernet solutions – while achieving the full performance of IO-Link.

ASi Cable = extremely simple installation + efficient power distribution

ASi or ASi 5 lets you take advantage of the proven piercing technology. Thanks to ASi piercing technology, modules are simply plugged onto the profile cable without a connector – with maximum contacting reliability. The profile cable is simply taken from the cable reel in the desired length and the modules are then placed exactly where they are needed, down to the millimeter. No unnecessary cable runs are needed, as is inevitable with pre-assembled cables, and no expensive connectors or T-pieces are necessary.

Switch instead of protocol converter

Unlike ASI-5, SPE does not require protocol converters. Through the physical layer of SPE, data is captured in a unified protocol at the information source (sensor) and transmitted via switches – non-smart distributors – to the output location of a network participant (computer). To prevent loss, this data is temporarily stored in the switch. The ASi-5 gateway, on the other hand, is a smart network participant with an integrated switch.

It additionally "translates" the data into ASi-5 ASIC for the higher-level control system. Likewise, the data – together with diagnostic messages – can also be viewed directly on the display or conveniently via remote access.

Communicative break between ASi-5 and TCP/IP increases cybersecurity

The number of smart components in the field is increasing exponentially in the age of Industry 4.0. Cybersecurity and network security are therefore becoming increasingly important. What security measures are required for SPE and which for ASi-5? The most important difference between the two technologies in this context is the ASi Gateway, which ensures a logic break between ASi-5 and TCP/IP and represents an additional “security door”. This break in communication isolates many network nodes and thus closes security gaps. Those who are responsible for network security can thus concentrate on significantly fewer devices and check them more carefully.

Another advantage: if you want to change the field bus protocol for ASi-5, you only need to replace the corresponding gateway. All ASi modules, sensors, and actuators can remain unchanged. With SPE, on the other hand, you have to secure not only a node (the gateway) but also all sensors and actuators against possible TCP/IP attacks. And if you change the field bus protocol, you often have to replace all sensors and actuators as well – unless they support the new protocol.

Conclusion: Single Pair Ethernet and ASi-5

What is the conclusion of the comparison between ASi-5 and Single Pair Ethernet? Making a final conclusion is not easy with the information available to date. The following statements can be made, however:

- "A lean, lightweight, yet high-performance Ethernet infrastructure was needed to enable the industry to digitize the field level and move towards IIoT." (Source: single-pair-ethernet.com)

- Single Pair Ethernet has its strengths thanks to high data size, high data volumes, and through the use of a switch instead of a protocol converter.

- ASi was developed for typical field applications in machines and systems, which is precisely where its strengths lie.

- ASi-5 replaces conventional Ethernet in many of today's applications, e.g., in drive technology or IO-Link.

- Both SPE and ASi can complement Ethernet in the field with their lean, lightweight, yet powerful infrastructure.

Users have a choice: Shielded/unshielded options are available for each SPE standard. However, these cable variants are not necessarily mentioned in the specifications. Depending on the standard, which in turn determines the speed, the cable length can be significantly increased by using a shielded SPE cable. For example, from 15 m (unshielded) to 40 m (shielded) at 1 Gbit/s as defined by 1000BASE-T1 or IEEE 802.3bp.

The SPE System Alliance consortium makes the following statement on its homepage (singlepairethernet.com): "A complete 360° enclosed stainless steel sheath surrounding the entire connector [SPE] provides excellent electromagnetic compatibility (EMC)." It can therefore be assumed that SPE is EMC-resistant in the industrial environment, especially with the connector and cable shielding mentioned above. Due to the current stage of development, no further details are available.

Since PROFINET is an Ethernet-based protocol, it can basically be transmitted via SPE. SPE is just a new physical layer, i.e., new hardware for the transfer of information from protocols such as Ethernet.

The different physical layers are connected via a switch to enable them to communicate with each other.

Due to the current stage of development, no precise details have been published to date. However, it can be assumed that the wiring in such an application scenario is based on the implementation using conventional Ethernet.

It would make sense to connect a switch with 32 ports, each with the data rate of 10 Mbit/s, to a control system via a 1 Gbit/s port. This is the only way to ensure that every port can use the full bandwidth at all times. Most SPE applications in the field could be a combination of switches and point-to-point connections. The point-to-point connections, each limited to 1,000 m in length, would connect the attached sensors to the switch