Vandværk øger sikkerheden og fleksibiliteten med ASi-5

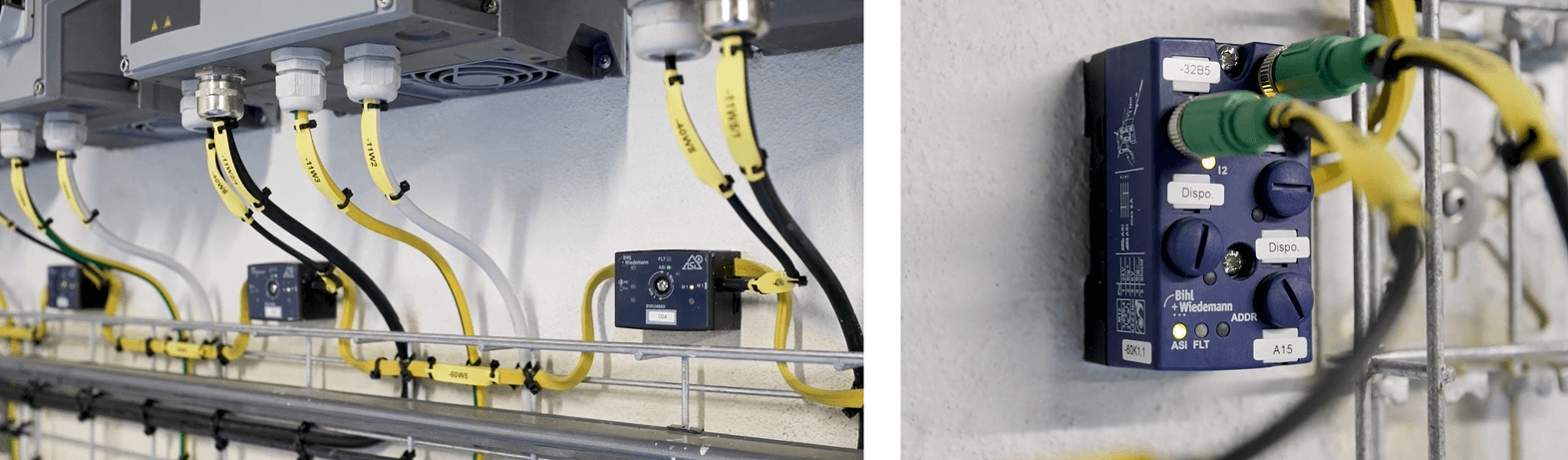

Englerup Vandværk i Vestsjælland har installeret et nyt SCADA-kontrolsystem – med en AS-Interface-løsning i centrum. Alle pumper, ventiler og andre komponenter er nu forbundet i et netværk, som styres af en ASi-master. Kabelarbejdet blev minimeret, fordi det 2-trådede ASi-kabel transporterer både data og strøm. Det er også nemt at udvide systemet, da en ASi Master kan håndtere mere end 100 enheder.

ASi-5 motormoduler er nemme at konfigurere

Løsningen omfatter også mange ASi-5 motormoduler BWU4980, som er specielt udviklet til Danfoss' frekvensomformere i VLT-serien. Takket være softwaren fra Bihl+Wiedemann er konfigurationen meget praktisk: Den foregår kun i den første frekvensomformer og kan derefter overføres til andre enheder.

ASi-5-teknologien muliggør hurtigere overførsel af større datamængder – og baner vejen for Industri 4.0. ASi-5 leverer korte cyklustider med op til 384 digitale ind- og udgange på 1,27 ms og er fuldt kompatibel med alle tidligere ASi-enheder og ASi-generationer.

Englerup har nu et fleksibelt, enkelt og pålideligt system og er ideelt rustet til fremtidige krav.

Wasserwerk erhöht Sicherheit und Flexibilität mit ASi-5

Das Wasserwerk Englerup im dänischen Vestsjaelland hat ein neues SCADA-Steuerungssystem installiert – mit einer AS-Interface Lösung als Herzstück. Alle Pumpen, Ventile und sonstigen Komponenten sind nun in einem Netzwerk verbunden, das von einem ASi Master gesteuert wird. Der Verkabelungsaufwand war minimal, weil das 2-adrige ASi Kabel sowohl Daten als auch Energie transportiert. Auch die Erweiterung des Systems ist einfach, da ein ASi Master mehr als 100 Geräte verwalten kann.

ASi-5 steuert Regalbediengerät sicher durch die Gassen

Für das neue Regalbediengerät (RBG) eines automatisierten Hochregallagers setzt Klinkhammer Intralogistics auf Sicherheitslösungen von Bihl+Wiedemann. Über Safe Link verbundene ASi-5 Safety Gateways ermöglichen die sichere Kommunikation zwischen dem fahrenden RBG und dem Schaltschrank. Das möglichst schnelle Beschleunigen und Abbremsen des RBG maximiert den Durchsatz von Waren.

ASi-5 simplifies RIELEC installations

Thanks to the ASi-5 technology, RIELEC Logistic Systems reduces installation costs and increases the flexibility of its projects. One of the key benefits of AS-Interface is that it enables machines to be assembled and disassembled quickly and easily. In addition, signals of all types can be easily integrated into the communication bus. The RIELEC Fit Sorter package sorter uses ASi-5 to control LED strips and to monitor conveyor belt sections. The ASi-5 gateways are responsible for collecting process and diagnostic information which is then transmitted to both the PLC and the cloud.

Predictive maintenance thanks to ASi-5 and IO-Link

SPAX International produces up to 50 million screws each day. To make the machines in production Industry 4.0-capable, the company relies on ASi-5/ASi-3 PROFINET gateways with an integrated safety monitor and compact IO-Link masters. The machines can be easily converted and now facilitate predictive maintenance. In addition to digital information, IO-Link devices can now also provide process and diagnostic values.

Danish brewery saves over 2.5 km of cable thanks to ASi

The brewery, which recently opened in April 2019, was designed and built by the brewery experts GEA Process Engineering A/S. All the brewery’s processes including ASi Masters and motors are controlled via PROFINET by two Siemens PLCs. All the brewery’s processes including ASi Masters and motors are controlled via PROFINET by two Siemens PLCs. All the tanks, kettles and plant components can be mutually connected by means of a system of 744 pneumatically activated process valves – controlled by eight ASi Masters from Bihl+Wiedemann. The ASi network also links together instruments and sensors that record the process data from each fermentation tank, such as the pressure, level and temperature.

Ardo A/S are now saving forklift time in their freezer room

LIP Bygningsartikler saves now 22% of the total cost on their conveyor modules thanks to an ASi solution from Bihl+Wiedemann. Each module and the complete system is connected through an ASi network with integrated safety from Bihl+Wiedemann. New conveyor modules can be added simply without additional wiring from the main PLC.

Building materials company simplifies wiring thanks to ASi

LIP Bygningsartikler saves now 22% of the total cost on their conveyor modules thanks to an ASi solution from Bihl+Wiedemann. Each module and the complete system is connected through an ASi network with integrated safety from Bihl+Wiedemann. New conveyor modules can be added simply without additional wiring from the main PLC.

Would You Like to Share Your Success Story?

Are you also enjoying the benefits of an exciting Bihl+Wiedemann application? And would you like to share your success story with interested people from all over the world? We would be delighted to present your story in an application report alongside an illustrative video. Get in touch with us!