IIoT and Industry 4.0 with Bihl+Wiedemann

ASi-5 – high data bandwidth for demanding applications

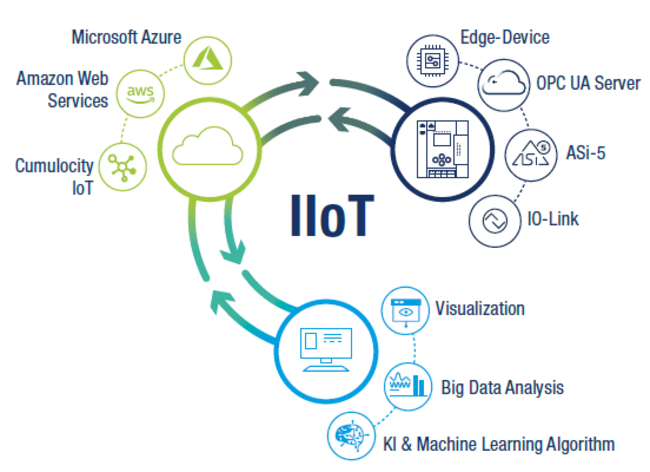

Machine data, process data and diagnostic data - today, machines and systems generate huge amounts of data. But only a fraction of this data necessarily belongs in the higher-level PLC. In order to successfully implement Industry 4.0 projects, the majority of the data needs to be processed and analyzed in IT. Coordinated interaction is only possible when all devices in the cyber-physical system communicate with each other.

A powerful data shuttle such as ASi-5 is needed. The new ASi generation offers a high data bandwidth and short cycle times. This makes it easy to integrate the smart sensors like IO-Link that are so important for Industry 4.0.

Our modern ASi-5/ASi-3 gateways also play an important role. They have two independent interfaces - for OPC UA and a fieldbus - which allow the respective data to be transferred directly to IT or the control. The gateways also act as a link between field devices and higher-level IT systems, collecting valuable diagnostic data that usefully supplements the device data from the field.

Since more connectivity increases cyber risks, we rely on encrypted communication and authentication. Thanks to field update capability, the ASi-5/ASi-3 gateways also meet future security requirements.

Content

- ASi-5 – high data bandwidth for demanding applications

- Our advantages with IIoT and Industry 4.0

- The ASi-5/ASi-3 Gateways cleverly separate IT from OT

- ASi-5/ASi-3 Gateways as edge device

- Bihl+Wiedemann meets increasing security requirements

- Use Case: connect IO-Link devices easily to the cloud

- OPC UA – universal data exchange from the sensor to the cloud

Our advantages with IIoT and Industry 4.0

Integrated OPC UA interface

All ASi-5/ASi-3 gateways are equipped with an OPC UA server, which enables direct data transfer between the field devices via ASi and IT systems - independent of the fieldbus. Thanks to the OPC UA Server, the data can be easily used in a cloud, on a local server or in a visualization tool.

Intelligent data separation

Thanks to two independent interfaces, our ASi-5/ASi-3 gateways enable consistent separation of OT (PLC) and IT (database systems). As the first component in the automation pyramid that can communicate via Internet protocols, the gateway is suitable as an intelligent data separation. Due to the network separation of IT and OT, the traffic on the fieldbus network can be reduced and accelerated.

Reduced

integration effort

An identification, authentication and certificate exchange are required to safely connect an edge device to the cloud. The one-time effort for this is the same for all edge devices. But with an Ethernet-based 8-port IO-Link master, for example, only eight IO-Link devices can be collected. In contrast, an ASi-5/ ASi-3 gateway can integrate several hundred IO-Link devices as well as other sensors and actuators.

ASi-5/ASi-3 Gateways as edge device

1. With only one ASi-5/ASi-3 gateway as edge device, the data of hundreds of sensors and actuators can be collected thanks to AS-interface – e.g. IO-Link sensors with valuable diagnostic data.

2. The data of all devices used is transferred via ASi to the ASi-5/ ASi-3 gateway with integrated OPC UA server. The summarized data then becomes available on the IT and OT interface.

3. The ASi Gateway transmits as an edge device all relevant data in cloud-based data systems via the Internet. There are two options for this: Either; an edge server prepares the data, and sends it to the cloud, or, the cloud retrieves the data itself from the OPC UA server.

4. The data is now available in the cloud and can be used as valuable information – e.g., for preventive maintenance or centralized real-time ERP inventory management.

Smart factory devices, such as decentralized inverters with IO-Link interface, are interesting for IT and OT. The process control (OT) handles the movement of the drive and adjusts the variable speed, ramp time and rotation direction, among other things. The IT systems can generate real added value through Big Data analytics, machine learning or AI algorithms. This involves evaluating diagnostic data such as heat sink temperature, power consumption or the operating mode of the drive. In many cases, a smart factory device generates far more diagnostic data than actual process data. Diagnostic data can be transferred from the ASi-5/ASi-3 gateway both via the fieldbus interface and via the diagnostic interface. In order to relieve the OT, with a fieldbus such as PROFINET and the real-time critical data, it is sensible to use a separate network structure for the IT. Thanks to the integrated OPC UA server, the ASi-5/ASi-3 gateway provides a secure and established IT interface.

Bihl+Wiedemann meets increasing security requirements

Due to the strong networking of Industry 4.0 devices, the topic of data security is becoming enormously important, since any device with access to other devices in a network can be used as an attack platform. We enable the seamless integration of our devices into existing IT security concepts and ensure data security like this:

All modern ASi-5/ASi-3 gateways can be updated and can meet future safety requirements long time after commissioning.

The firmware on the update server is signed.

- Each TCP/IP-capable device receives an individual certificate for SSL communication in production.

ASi increases security through the communicative break between TCP/IP and the field devices.

OPC UA uses established encryption methods such as AES-256 with SHA up to 512 or RSA.

Software updates and OPC UA can also be locked locally on the device - a reliable and absolute protection.

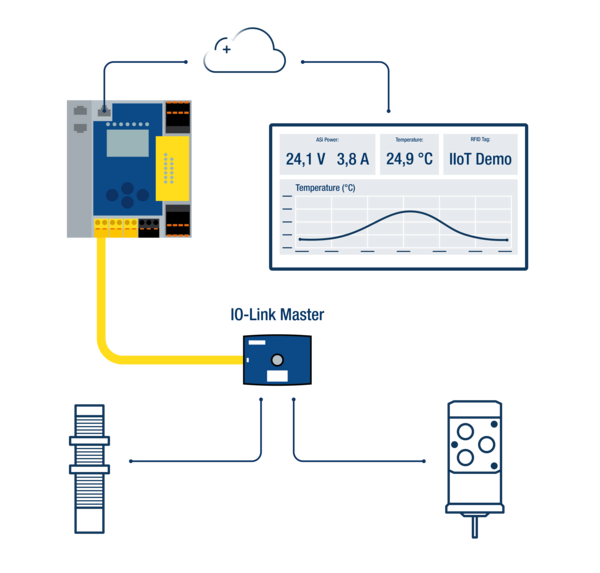

Any IO-Link devices (here an RFID station and a temperature sensor) can be connected to ASi via ASi-5 modules with integrated IO-Link master (BWU4077).

The data of the IO-Link devices is sent to the cloud (here AWS from Amazon) via the integrated OPC UA server of the ASi gateway (BWU3674).

In addition to the IO-Link process data, gateway diagnostics (including current and voltage from the ASi circuit) are also transmitted as OPC UA objects.

An AWS IoT certificate and private key is generated and linked to a script-based edge server.

The certificate enables a unique connection between OPC UA Server and OPC UA Client, which is integrated with the cloud-based database.

The script-based edge server regularly sends prepared data packages directly to the cloud.

The data is clearly visualized in a dashboard.

OPC UA – universal data exchange from the sensor to the cloud

In the age of Industry 4.0, data collected from sensors and actuators via ASi is no longer just indispensable for the control. Higher levels such as remote maintenance servers, visualization systems, and cloud-based applications also require reliable, semantic data from the lowest field level.