IIoT and Industry 4.0 with Bihl+Wiedemann

ASi-5 – high data bandwidth for demanding applications

Machine data, process data and diagnostic data - today's machines and systems generate huge amounts of data. But only a fraction of this necessarily belongs in the higher-level PLC. In order to successfully implement Industry 4.0 projects, the majority of the “valuable” sensor data (e.g. operating hours and switching counters) must be processed and analyzed in the IT system. This is often not the case due to the high level of integration required. How can coordinated interaction be achieved? Only if all devices in the industrial network communicate with each other.

IT interfaces and a robust data shuttle like ASi-5 are in demand. A powerful data shuttle such as ASi-5 is needed. The new ASi generation offers a high data bandwidth and short cycle times. This makes it easy to integrate the smart sensors like IO-Link that are so important for Industry 4.0.

Our modern ASi-5/ASi-3 gateways also play an important role. They have two independent interfaces - for OPC UA, REST-AP and a fieldbus - which allow the respective data to be transferred directly to IT or the control. The gateways also act as a link between field devices and higher-level IT systems, collecting valuable diagnostic data that usefully supplements the device data from the field.

Since more connectivity increases cyber risks, we rely on encrypted communication and authentication. Thanks to field update capability, the ASi-5/ASi-3 gateways also meet future security requirements.

Our advantages with IIoT and Industry 4.0

Integrated

IT interface

All ASi-5/ASi-3 gateways are equipped with an OPC UA server and with a REST-API interface.This facilitates direct data transfer between field devices via ASi and IT systems like cloud, local server, or visualization tools – completely independent of the fieldbus.

Moderne

IT security concepts

Cybersecurity is our highest priority. We work ceaselessly on enhancing the IT security of our devices. We offer robust encryption methods, signed updates, customer-specific certificates, and much more.

Reduced

integration effort

The initial cybersecurity effort is uniform across all edge devices. An Ethernet-based 8-port IO-Link master can generally collect eight IO-Link devices. Conversely, an ASi-5/ASi-3 Gateway can integrate several hundred IO-Link devices along with other sensors and actuators.

Clever separation of IT and OT with ASi-5/ASi-3 Gateways

Smart factory devices like a decentralized inverter with an IO-Link interface are useful for both IT and OT. Process control (OT) handles drive movement, regulating variable speed, ramp time, and rotation direction. IT systems can create real added value through big data analysis, machine learning, and AI algorithms. They evaluate diagnostic data like heat-sink temperature, power consumption, and operational stress on the drive. Often, smart factory devices offer significantly more diagnostic data than actual process data. Diagnostic data can be transferred on both the fieldbus interface and the diagnostic interface of the ASi-5/ASi-3 Gateway. The requirements for the interfaces vary greatly: process control requires relatively little data, even at the maximum cycle time. Conversely, IT can handle large amounts of data, where transfer time is less critical. The two independent physical interfaces allow separate networks to be established if necessary.

Bihl+Wiedemann meets increasing security requirements

The extensive networking of Industry 4.0 devices underscores the growing importance of data security. Ultimately, any device that is able to connect with other networked devices can serve as a potential attack platform. Due to ever-evolving attack scenarios, we protect our devices (gateways and modules) with security updates throughout their entire product lifecycle. We also facilitate seamless integration of our devices into existing IT security frameworks, ensuring data security in the following ways:

With ASi-5, there is a logical separation between the field level and the network infrastructure (TCP/IP). The ASi Gateway acts like a firewall for the field level. As a communication protocol, ASi-5 presents an additional barrier against cyberattacks between the network infrastructure, ASi-5 modules, and their connected peripherals.

Firmware-Updates

Our signed firmware updates are safeguarded by matching the serial number and software version with the update server. The user decides whether and when to perform a firmware update or switch off the ports.

Authentication and encryption procedures

Bihl+Wiedemann employs modern encryption methods, such as AES-256 with SHA up to 512 and RSA. We also utilize both self-signed electronic certificates and customer-specific certificates. As cybersecurity requirements grow, the authentication methods that we employ – such as user management and enhanced password protection – are continually optimized.

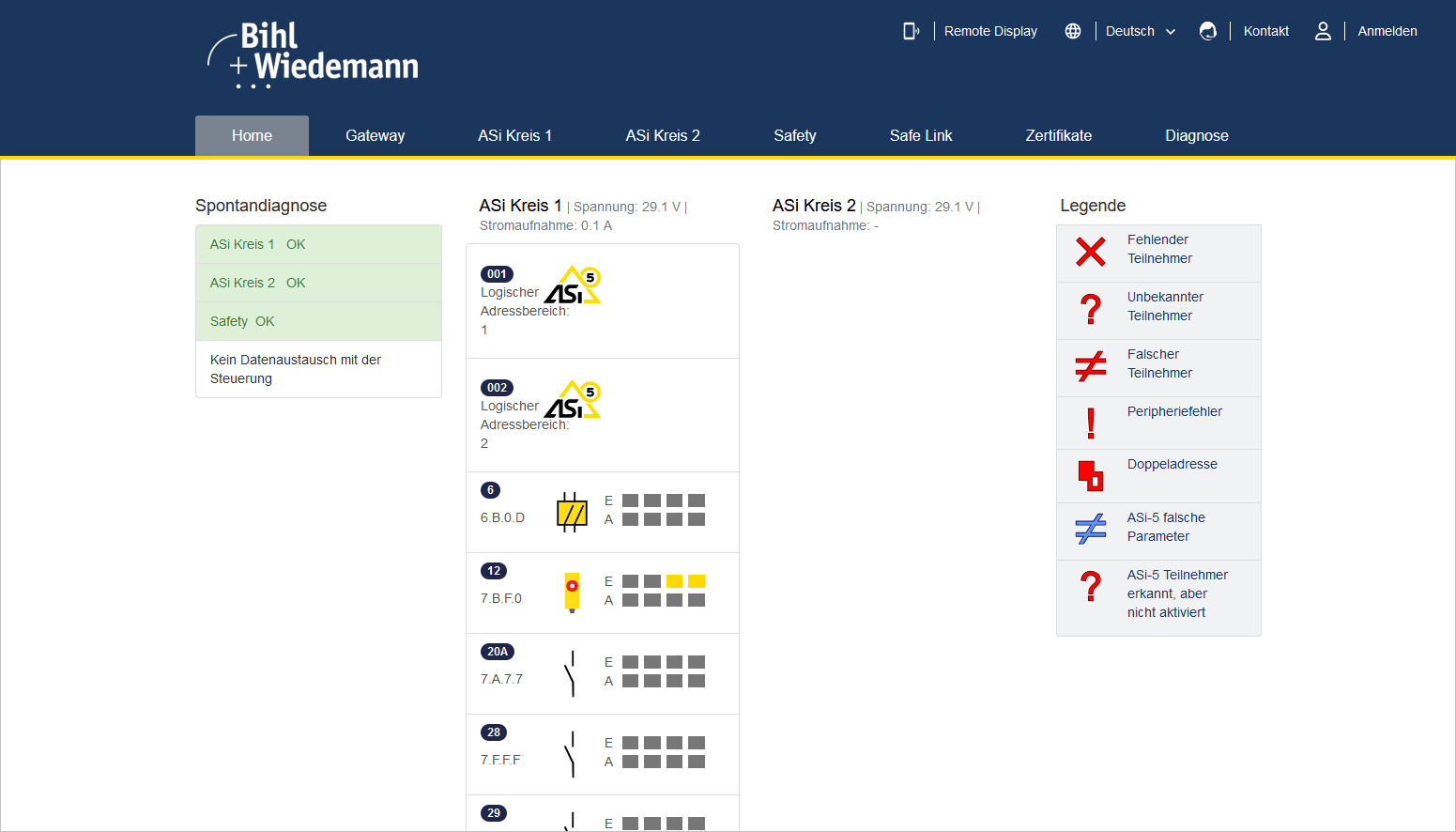

Web server in Bihl+Wiedemann gateways

The web server integrated into our gateways is universally applicable – it can be used on any display medium (smartphone, tablet, or PC), independent of the fieldbus in use. This fast, secure web server is user-friendly and assists in straightforward diagnostics and maintenance.

Main functions of the web server

Intuitive testing of process data even without a PLC connection

Comprehensive diagnostics for each ASi node

Remote display for controlling the ASi Gateway, e.g., for PROFIsafe address, iPar-CRC, and activation of firmware updates

State of the configured safety functions

Addressing of the ASi nodes

Resetting ASi nodes and the ASi Gateway

Logbook with historical errors

OPC UA user management and certificate management

OPC UA

The OPC UA server in our ASi-5/ASi-3 Gateways allows you to access a wide range of machine data. It's easy to retrieve a wealth of information about the machine and the process, from device diagnostics to process data, via the network.

REST-API

Modern ASi-5/ASi-3 Gateways all feature a REST-API interface that provides you with effortless and direct access to machine data and system information – with no impact on ongoing fieldbus communication.

IO-Link

Integrate a wide range of IO-Link devices conveniently and economically. The main advantages of our solution: a great freedom in the choice of topology, reduced wiring effort without switches, a smart power supply concept and cost-effective IO-Link masters with up to 8 ports.

Cybersecurity

All modern ASi-5/ASi-3 Gateways are updateable and, with signed firmware, can meet future safety requirements long after commissioning. What's more, the communication gap between ASi and TCP/IP enhances cybersecurity. Find out more.