Less connectors – More connection. Using AS-Interface.

Great things come from a pioneering spirit

It is common knowledge that simple solutions are often the best. Simplicity is also the major feature of AS-Interface (ASi). No connectors, one cable, the best possible connections – ASi has a lot to offer. The fieldbus system not only helps to save costs for connectors and other components, but also conserves valuable resources.

ASi also offers other advantages: For example, you can realize functional safety with ease, integrate IO-Link very conveniently, solve complex drive control requirements effortlessly, or implement Industrial Internet of Things (IIoT) cost-effectively.

No matter what automation tasks you implement with ASi in a wide range of industries: wiring will always be a breeze.

Why do I need less connectors for AS-Interface?

Connectors are common and indispensable in round cable solutions – both for the bus connection and for the power supply. To connect just two modules in the field, two pre-assembled cables and therefore four connectors are required. In the case of larger systems with Ethernet solutions, this quickly adds up to several hundred connectors.

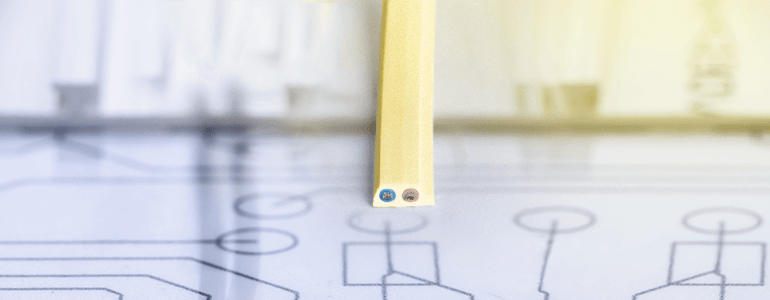

AS-Interface takes a revolutionary approach here – virtually without plugs and sockets. The solution: piercing technology. The profile cable, which is protected against polarity reversal, is simply inserted into the module. With Bihl+Wiedemann's solution, at least four gold-plated needles then penetrate vertically at all times and ensure perfect contact. The yellow ASi cable transmits data and power, whereas the black profile cable optionally provides 24 V or 48 V auxiliary power. Assembly and disassembly of the top and bottom parts of the module is also incredibly easy.

With ASi installations, you only ever need one connector for the fieldbus connection to the ASi gateway – regardless of how many modules are being used. And you can do even more than just connect the ASi modules to the profile cable at any point. Thanks to the piercing technology, you can also easily replace, move, or add modules. The installation of ASi systems is therefore fast, flexible, and cost-effective.

And how is it that less connectors actually provide more connections? That's because you can connect additional modules at any point between existing modules without the need for a connector. With Ethernet solutions, this requires considerable time and effort. "More connections" also comes from the fact that ASi enables an extremely large number of modules to be connected to the control system. All you need is one connector and a single IP address: that of the gateway.

Why is AS-Interface a cost-effective wiring system?

Thanks to profile cables and piercing technology, ASi wiring couldn't be any more simple because you don't need different pre-assembled connection cables, so you spare plenty of costly assembly time. You do not need to know the length of the cables used beforehand because ASi gives you the flexibility to decide on site where you want to install the modules on the profile cable. This noticeably reduces the planning effort and achieves a further cost advantage.

Wiring costs with ASi are significantly lower than with other fieldbus systems. As shown in the calculation below, our product lets you save up to 68 percent. Last, but not least, with ASi solutions by Bihl+Wiedemann, your overall costs will also decrease in many cases.

Why is AS-Interface a resource-saving technology?

Today, AS-Interface (ASi) is more future-proof than ever. Because one thing is certain for us: The more environmentally friendly the solution, the better its prospects. AS-Interface has a lot to offer in this respect - especially in comparison to other automation systems at the field level:

Less plastic + less copper = less resource consumption *

* The comparison assumes that the energy used is produced in an ideal state in systems with ASi and without ASi in a climate-neutral manner.

Less cables

In an ASi network, significantly less cable is required compared to conventional parallel wiring. This leads to savings in valuable resources such as copper or plastic. As a result, the total energy consumption for cable production is significantly reduced. And this also has a positive environmental effect when it comes to disposal - less waste is produced.

Plugs and sockets are not required

Since the AS-Interface system does not require plugs and sockets, the resources needed to manufacture these components can be saved completely. The reduction in the use of materials lowers the demand for raw materials and energy. As a result, the costs for production and disposal are eliminated and the environment is protected.

Simple switching off of ASi circuits

All modern ASi-5/ASi-3 gateways have a switch to de-energize connected ASi circuits. If a plant section is currently not required, all ASi modules and the sensors supplied from ASi can simply be switched off. Instead of 2-8 A (depending on the ASi circuit), the current, which then only supplies the 30 V power supply and the gateway, drops to less than 0.2 A. When the ASi circuit is switched on again, it is ready for operation within a few seconds.

Less plastic, less copper – better for the environment

Independent of system and manufacturer

The ASi technology is compatible with almost all common fieldbus systems. It does not matter whether PROFIBUS, PROFINET, CC-Link, EtherNet/IP etc. are used at the higher levels.