Diagnostics with Bihl+Wiedemann – as easy and user-friendly as ASi

Wide range of diagnostic options

Diagnostics are indispensable for machines and systems – during commissioning, monitoring/maintenance and, of course, troubleshooting. Bihl+Wiedemann offers numerous diagnostic tools and a wide range of display options for every field of application. What is special about this: The diverse diagnostic options are as easy and user-friendly as the AS-Interface wiring system itself.

Our ASi devices also offer various diagnostic functions: For example, the display of the ASi gateways shows a brief description of any errors that may occur. On the other hand, if you see a "smiley", it means that everything is OK. Individual diagnostic values can also be evaluated in detail via the menu. New ASi-5 modules with channel-specific diagnostics also make it possible to individually detect an output short circuit or sensor supply overload at each connection. Moreover, thanks to the field update capability of our devices, their diagnostic options can also be further extended.

On this page, you will learn about our wide range of diagnostic options, some of which might rarely be used in practice. That is because ASi networks are very robust, and errors are thus rather unlikely to occur during operation.

Commissioning

Addressing, configuration and commissioning of ASi circuits is extremely easy with our intuitive software (Bihl+Wiedemann Suite/Bihl+Wiedemann Safety Suite). The ASi Control Tools360 are available for standard hardware, and our safety software ASIMON360 is used for functionally safe applications. Both software solutions offer the following features:

- The hardware catalog covers the entire product range of Bihl+Wiedemann. When configuring the ASi circuit, it is sufficient to click on the corresponding device; any settings will then open automatically. This helps to avoid planning errors, e.g. with regard to network or fieldbus utilization.

- The commissioning wizard guides the user step by step through the addressing and configuration of the connected modules. Deviations or errors during commissioning are displayed directly.

For easy and safe commissioning of your ASi system, also use the modern ASi-5/ASi-3 Address Programming device – in combination with the Bihl+Wiedemann Suite. In this way, you combine the advantages of decentralized addressing with those of centralized planning and parameterization.

Diagnostic software provides detailed test reports

Our diagnostic software provides valuable services during the acceptance of systems. They help you to check the installation for any errors before delivery. During the acceptance measurement, a detailed test report that includes the documentation is automatically generated as a PDF.

Predictive maintenance

The cyclic diagnostics feature of the control system plays an important role for continuous monitoring of systems: The automatic, cyclic readout of lists (e.g., peripheral fault and configuration error list) is used for continuous error checking in the ASi network. Since data can be used and evaluated in the control system, it can be mapped on an HMI, for example. You can also program how the control system should react to certain errors, e.g., by switching off "affected" plant sections in a targeted manner.

Other diagnostic tools or options that you can use for monitoring the system:

- The diagnostic software checks the actual status of the system. Among other things, it provides information on the quality of the entire ASi installation and potential communication faults. This enables early detection of deteriorating transfer characteristics and implementation of preventive measures (predictive maintenance).

- The online bus information (function in ASIMON360/ASi Control Tools360) enables easy diagnostics on modules as well as live monitoring and testing of inputs and outputs. Errors in the ASi circuit, such as unconfigured nodes, are clearly indicated through plain symbols, which can be easily understood by everyone.

- Thanks to the OPC UA interface in our gateways, a wide variety of machine-related and diagnostic data can be easily retrieved – in a cloud, on a local server or in a visualization tool. OPC UA also supports you in successfully implementing predictive maintenance for the entire system. Diagnostics/Rectification of Errors To avoid costly downtimes, errors must be rectified quickly. Meaningful or detailed diagnostics as well as quick and concrete proposals for solutions are indispensable. In this respect, Bihl+Wiedemann supports you in many ways.

Troubleshooting

To avoid costly downtimes, errors must be rectified quickly. Meaningful or detailed diagnostics as well as quick and concrete proposals for solutions are indispensable. In this respect, Bihl+Wiedemann supports you in many ways.

Diagnostic software facilitates troubleshooting

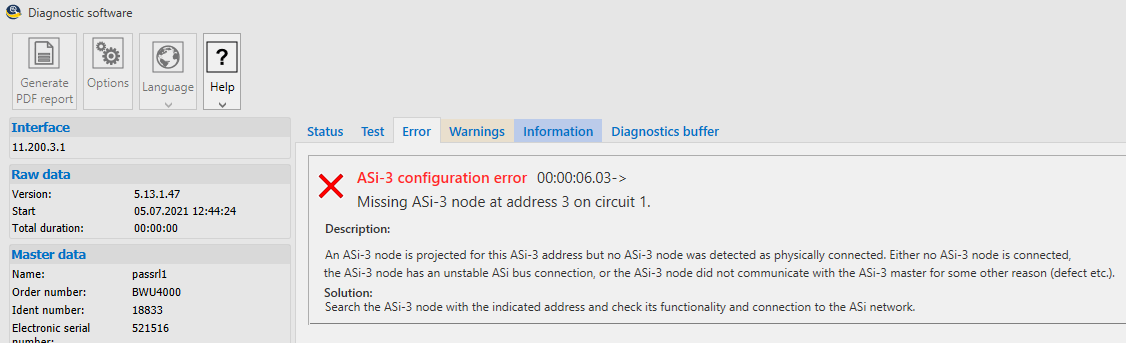

Our diagnostic software – which is included in the Bihl+Wiedemann Suite or Bihl+Wiedemann Safety Suite – turns any commercially available PC into an ASi diagnostic device. Just like a diagnostic device for cars, the diagnostic software reads error logs, checks the running system, and provides many concrete suggestions for solutions. Specifically, it offers you the following options:

- Examination of bus information such as values of voltage, current and voltage symmetry as well as configuration, peripheral and telegram errors

- Additional analysis of ASi Safety at Work through diagnostics of safe inputs and safe outputs as well as Safe Link connections

- Reading out the historical diagnostic data from the diagnostics buffer of the gateway

- Differentiation of different types of ground faults

- Concrete information and suggested solutions offer direct "assistance for self-help" in the event of errors occurring during the test

Simplified device replacement

Auto-addressing facilitates the commissioning of replacement devices. In this context, it is also advantageous that ASi can even allow automatic simultaneous replacement of several different faulty modules. Moreover, the address programming device is a convenient tool for manual addressing directly at the modules.

Web server enables fast system diagnostics

The web server integrated in our gateways enables fast system diagnostics. You can use it on any display medium (from smartphones, tablets to PCs), independently of the specific fieldbus. The spontaneous diagnostics features in the gateway displayand the webservers remote display provide support without software and PLC.

Automatic channel diagnostics for PROFINET

The channel diagnostics for PROFINET is automatically available in the control system. It helps you evaluate detailed diagnostics in the control system and even provide them automatically to the user – without programming work – by means of plain text messages on a visualization system or HMI.

Channel-specific diagnostics

Many modules, such as the BWU4230 with its 16 self-configuring I/Os, are designed for channel-specific diagnostics. This enables individual detection of an output short circuit or overload of the sensor supply at each connection. This allows errors to be localized and rectified quickly. Furthermore, the combined use of our diagnostic software with active assistance makes system troubleshooting even easier.

Five steps for troubleshooting/rectification of errors

If you want to troubleshoot and rectify an error, you can use the following diagnostic tools sequentially – and extend your diagnostic depth further and further:

1. Gateway display

Here you get initial spontaneous diagnostics as a plain text message in the switching cabinet.

2. PROFINET channel diagnostics

You can also have the plain text messages displayed automatically on a visualization system or HMI embedded in the machine, without any additional programming work.

3. Webserver

It provides you with more detailed diagnostics independent of the terminal device – simply via the web browser without requiring any additional software.

4. Online bus information and diagnostic software

They provide you with further assistance on individual problems. The PC software also allows you to test the functionality by reading inputs and setting outputs. To use the online bus information, please open ASi Control Tools360 or ASIMON360 and connect to the gateway.

5. Control system

By programming accordingly, you can create unique application-specific diagnostic messages.