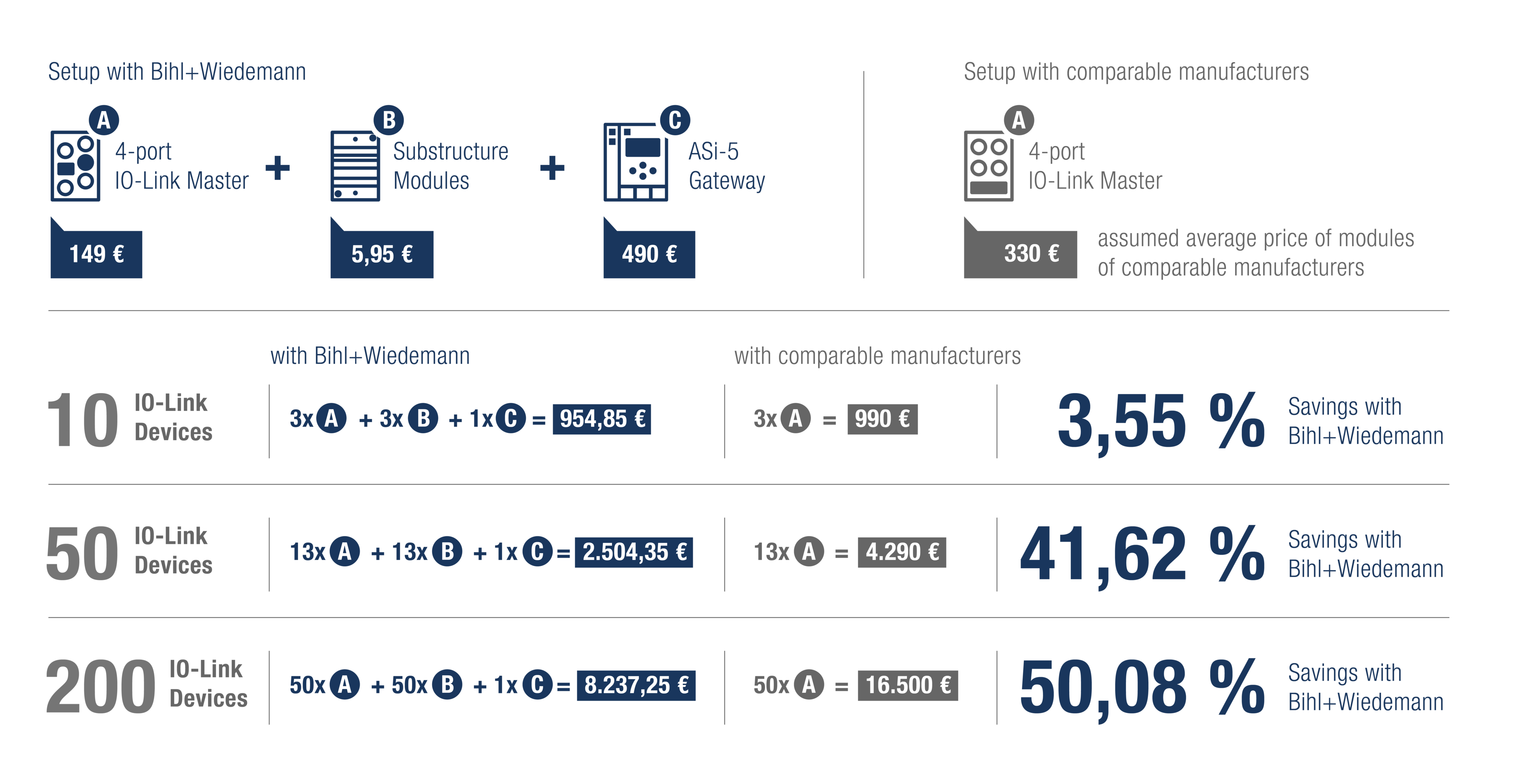

Cost comparison IO-Link - You save up to 40 % with 50 devices

In many application scenarios, IO-Link solutions from Bihl+Wiedemann are much more cost-efficient than similar solutions from other providers. An application with Bihl+Wiedemann is already cheaper than comparable PROFINET variants from three 4-port IO-Link masters. Another factor is the finer granularity. Our 1-port IO-Link master allows you to integrate an IO-Link device exactly where you need it. Thanks to piercing technology, it is extremely easy to install our IO-Link master. You can substantially reduce the time required for assembly.

The larger your application, the more you save

The more devices you need for your control system, the greater your cost advantage when you choose an IO-Link solution from Bihl+Wiedemann. For example, in a medium-sized application with 50 IO-Link devices, you can save up to 40 %* against a comparable PROFINET, EtherNet/IP or EtherCAT version.

With 50 devices*, you can save up to 40 %

The price comparison is based on the following assumptions:

- Only 4-port IO-Link masters with 4 ports each are used or compared.

- IO-Link devices (sensors or actuators) can only be connected using an IO-Link master. A maximum of 4 IO-Link devices can therefore be connected to a 4-port IO-Link master. Therefore, three 4-port IO-Link masters with a total of 12 ports are required to connect 10 IO-Link devices.

- The price comparison based on list prices does not take discounts into account. These must be included for exact cost comparison.

- Further cost savings through to the simple AS-Interface wiring system are not included in the price comparison.

- Status:06/2024

Reduce additional costs by connecting digital I/Os directly

IO hubs and IO-Link master ports are often used to collect many digital I/Os – there is great saving potential in this respect. Simply use a Bihl+Wiedemann ASi-5 self-configuring I/O module: The 16 digital signals of the BWU4230 can be distributed freely as inputs or outputs – and can be connected without having to pass through IO-Link. By simply integrating digital I/Os via ASi, you do not need any additional IO-Link master ports just for standard signals. At the same time, you eliminate the need for the M12 connection cable between IO-Link I/O hubs and IO-Link master ports. The maximum IO-Link cable length of 20 meters is also irrelevant. That's because piercing technology enables you to distribute the digital I/Os anywhere along the ASi line with a length of up to 200 meters. Here you can find additional information about the ASi-5 self-configuring 16 I/O module.

Advantages of the Self-configuring I/O Modules

- Sensors and actuators can be connected in any combination; offering you the possibility of having 2 signals per M12 connection

- No M12 ports go unused thanks to a product portfolio that offers options from 4 I/Os to 16 I/Os

- 16 inputs/outputs with ASi-5 in 1.27 ms

- Cost-effective and fast collection of many inputs and outputs

- Various connection types – the ASi/AUX connection is made via

IO-Link mit Bihl+Wiedemann: Easy, flexible & cost-effective

Bihl+Wiedemann offers a well thought-out concept for the integration of IO-Link. You benefit from freedom of topology, reduced wiring complexity without switches and a smart power supply concept. Further advantages include reduced IP management complexity and low-cost IO-Link masters, which we provide with 1, 2, 4, and 8 ports.

What is IO-Link?

IO-Link devices are nowadays common in machines and systems. This is because IO-Link allows sensors and actuators to be connected to the control level via a cost-effective point-to-point connection. Find out more about IO-Link and the associated advantages here.