- AS-Interface

ASi-5: high-performance data shuttle for digitalization in process technology

… as an established fieldbus solution for the first automation level, ASi-3 has long enjoyed an excellent reputation in process technology. The standard is already widely used there, with its typical yellow profile cable for the simultaneous transmission of power and data. Its strengths include simple planning, the uncomplicated wiring concept with less connectors and no pre-assembled cables, simple integration of valves, for example, at the ideal wiring point, great freedom in topology selection, time-saving commissioning, convenient diagnostics, and ease of expandability.

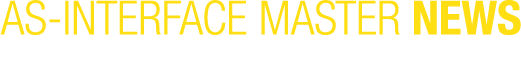

And: the high level of future-proofing thanks to the introduction of ASi-5. This is because wherever ASi-3 is already being used in process technology, systems can be made directly ready for the digitalization of process technology by extending them with ASi-5. This means that the infrastructure already in place can still be used – especially as the components from Bihl+Wiedemann, for example, are extremely compact and space-saving.

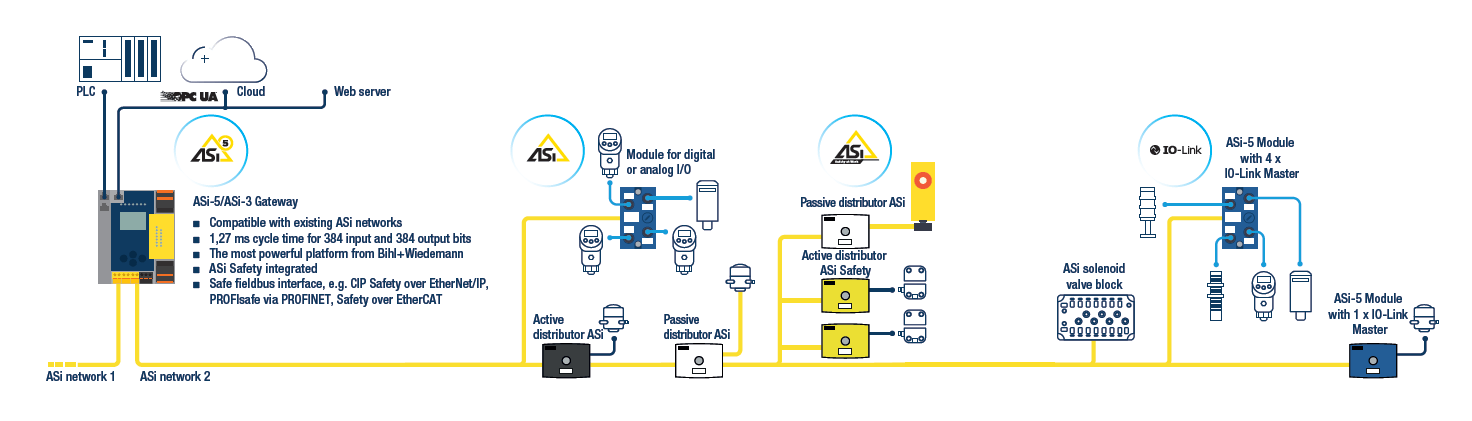

This is just one of the reasons why leading manufacturers such as GEMÜ, SPX FLOW and Sitomatic also offer valves and process technology components with an ASi-5 interface. All products are already integrated in the Bihl+Wiedemann software suites and can therefore be used in conjunction with the ASi-5 products of the German company. And by using the ASi-5/ASi-3 Gateways with OPC UA and REST API, these ASi networks can also be integrated in solutions such as the ABB FIM (Field Information Manager) device management software for configuration,

commissioning, diagnostics and maintenance of field devices.

Some manufacturers of process technology components have been working with ASi technology for well over 20 years – and know the advantages of transmitting data and power via one single cable and simple wiring using piercing technology. They confirm three things in particular: Firstly, there is no wiring technology that is simpler, more flexible, more reliable and ore cost-effective in terms of installation costs than ASi. Secondly, AS-Interface has been an established standard in process technology for many years – especially in the chemical, pharmaceutical, food, biotechnology and process engineering sectors. Users around the world use ASi to automate field devices, for example, in valve terminals or for binary end position detection of process valves. Thirdly, its costeffectiveness makes ASi in the latest ASi-5: high-performance data shuttle for digitalization in process technology and is already in great demad by many companies in these sectors when it comes to equipping their systems.

Digitalized process technology: ASi-5 as high-performance data shuttle

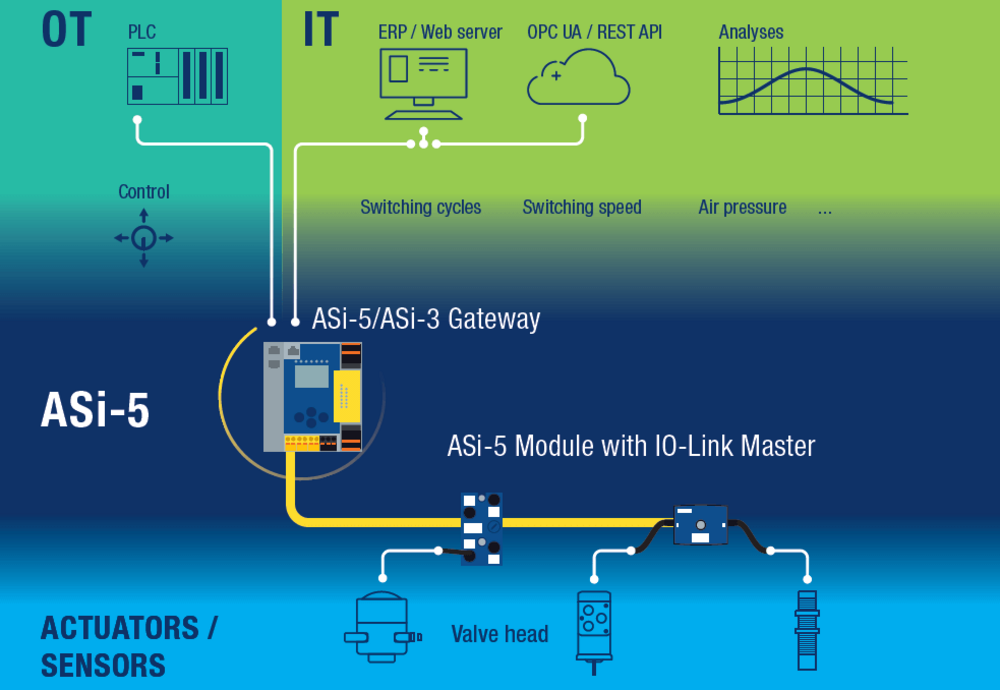

As a high-performance data shuttle, ASi-5 now makes it possible to transfer even more extensive data, such as analog values for controlling the valve position, diagnostic data from valve terminals and from their operating environment, and – thanks to the ASi-5 Modules with integrated IO-Link Master – also data from the world of smart IO-Link sensors and actuators with even shorter cycle times, for example, to make them available directly in IT applications such as condition monitoring via OPC UA or REST API.

In addition, ASi-5 can also be used to transport safe data and standard data on one single cable. This makes it just as easy to reliably monitor a door lock using AS-Interface, for example, during a cleaning process, as it is to monitor analog signals such as temperature, pressure or fill level. Finally, the ASi-5/ASi-3 Gateways feature modern security methods such as certificates and their management to make communication with the IT – separate from the OT – as secure as possible.

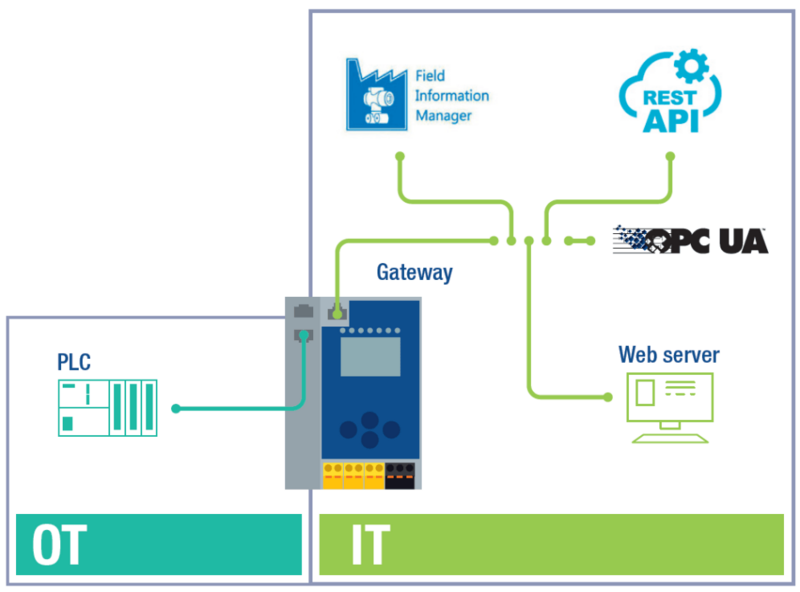

Experienced automation engineers will immediately think of IO-Link and its functionalities when they consider the performance features of ASi-5 – and for good reason. Both technologies are comparable in terms of data volumes and transmission speeds and complement each other perfectly: IO-Link, as a point-to-point connection protocol, can be ideally integrated into and transported over ASi-5 as a wiring system. This makes it possible to add IO-Link devices to the ASi network via ASi-5 modules with IO-Link masters, where the integrated ASi-5 connection is still missing in process technology solutions today.

Advantages of ASi-5 in process automation

ASi-5 convinces with high data transmission speeds and high data bandwidth. Together, these two factors make it possible to implement the ever-increasing device requirements associated with digitalization. In the case of valves, for example, additional information such as the air pressure in the valves for localizing leaks when using compressed air or the number of switching operations through to the path measurement of the valve stroke for the early detection of wear can be easily provided.

Field level products – standard and smart sensors and actuators, as well as safety and standard devices – can be fully integrated into a digital network via ASi-5. This means that users in process automation not only benefit from being able to parameterize devices and receive their diagnostic data via the network with ASi-5/ASi-3 Gateways from Bihl+Wiedemann, but also from being able to read process data.

Since these gateways are also equipped with OPC UA, the communication standard for Industry 4.0 and the IIoT, as well as the application programming interface REST API, the process data – which is usually irrelevant for the actual machine and installation control – can be provided directly in IT applications, bypassing the OT. Companies working with ABB FIM – the Field Information Manager from ABB – can take in OT and IT data via the ASi-5/ASi-3 Gateways from Bihl+Wiedemann – and in this way, communicate with valve islands and other devices, monitor them and document their parameters or changes.

ASi Safety: functional safety directly integrated

AS-Interface and ASi Safety can be used independently of the generation, system, and manufacturer. Because all common fieldbus systems are supported, functional safety can always remain exactly the same, regardless of the control system used. Since the safety technology can be implemented on the same two-conductor cable as the transmission of standard signals, there is no need for a costly, duplicate infrastructure. This means that ASi Safety can be used to implement many different applications in process automation simply and cost-effectively – from classic E-STOP buttons, safety doors and light curtains to the safe monitoring of temperature and pressure.

Save costs with ASi-5

Since the process industry is also under a great deal of cost pressure today, the fact that installation costs can be significantly reduced makes ASi technology interesting for many companies because there is no other wiring alternative that is simpler, more flexible, and more reliable. And wherever ASi-3 is already in use, no new or additional infrastructure needs to be installed to upgrade to ASi-5 because the yellow profile cable can be used by both ASi generations.

This also makes it cost-effective to connect sensors and actuators directly to ASi-5, for example, in the valve head, since there is no additional wiring effort required for digital inputs and outputs. However, if necessary, there are other options because digital and analog inputs and outputs, IO-Link sensors, or even serial protocols such as RS232, RS485, or CAN can be easily integrated with the appropriate ASi-5 modules.

And on the IT side, a solution with ASi-5 also offers real monetary advantages because more than 100 field devices can be connected to a single ASi-5/ASi-3 Gateway from Bihl+Wiedemann. The gateway itself requires only one single IP address in the network and communicates with the IT via a single – physically separate – interface using OPC UA or REST API. This reduces the number of IP addresses, the complexity of planning and operating networks – and thus the costs of digitalization.

ASi-5: enabler of future-proof digitalization in process automation

ASi-3 has successfully established itself in process automation thanks to its simplicity and cost-effectiveness. And in doing so, it has also paved the way for the new ASi-5 technology standard. This offers a wide range of features for significantly increasing system performance. It also opens up a wide range of possibilities for driving forward digitalization in these industries in a cost-efficient and future-proof way.

In industrial environments, the topic of datasecurity is highly relevant due to its great importance for production stability and process reliability in process automation. ASi-5 and ASi-5 Safety offer the highest level of cybersecurity for two reasons. Firstly, data transmission is carried out using Orthogonal Frequency-Division Multiplexing (OFDM). This dynamic frequency allocation makes it very difficult to intercept the messages exchanged, and only possible if the entire context of the connection establishment between the ASi master and ASi node is known.

In practice, this makes ASi-5 and ASi-5 Safety virtually tap-proof. On the other hand, the ASi-5/ASi-3 Gateways decouple TCP/IP and ASi-5 / ASi-5 Safety, i.e. the fieldbus and the field level. Thanks to ASi, no Ethernet port is required in the field. The gateway in the control cabinet thus becomes the only cybersecurity-relevant component of the entire installation, while the modules and nodes in the ASi network must fulfill far fewer security requirements. This makes it much easier to ensure cybersecurity in such systems.