Packaging automation with ASi – simple, flexible, resource-saving

Content

- Piercing technology

- Safety Basic Monitor

- Safe coupling Safe Link over Ethernet

- Packaging solutions for your system

- Advantages at a glance

- Easy integration of safety switches and door locks in ASi

- Data and power on one cable

- With fieldbus interface

- Fields of application for packaging technology with Bihl+Wiedemann

- Products and solutions for packaging automation

Packaging solutions for your system

Packaging automation is an ideal field of application for AS-Interface (ASi). This is because the advantages of our hassle-free wiring system come into their own here – e.g., in packaging machines, robots, palletizers, pallet stretchers, strapping machines and shrink-wrapping machines. The proven advantages of ASi include the ability to supply voltage and communication data on a single cable, as well as simple wiring thanks to piercing technology. This is complemented by a flexible topology and the transmission of safe and standard signals on the same cable.

Thanks to ASi-5 – the latest generation of AS-Interface – you now have maximum convenience and economy when integrating a wide variety of (smart) IO-Link devices, such as distance sensors or signal lights, which are becoming increasingly important in packaging automation. ASi-5/ASi-3 gateways with an integrated OPC UA interface also facilitate straightforward transfer of IIoT-relevant data to cloud-based databases. With our ASi-5 motor modules, you can also efficiently control 24 V and 48 V motorized rollers from suppliers such as Interroll, Itoh Denki and RULMECA and many others. As for frequency inverters, we offer solutions for SEW, NORD, Lenze, Rockwell and Bonfiglioli, for example.

Functional safety is also unproblematic with ASi. Safety components such as E-stop buttons, safety switches, door locks and light barriers, which are important in packaging automation, can be seamlessly integrated.

Proven

ASi advantages

With AS-Interface, you always benefit from a drastically reduced wiring effort. Compared to round cable solutions, wiring costs can be reduced by around 68%. Thanks to piercing technology, you can easily connect or relocate modules – with maximum contacting reliability. Other advantages of ASi include free choice of topology and cost-efficient integration of safety on the same infrastructure.

Simple IO-Link

integration

Integrate a wide range of IO-Link devices such as optical distance sensors or signal lights with maximum convenience and economy. We offer you inexpensive IO-Link masters with 1, 2, 4 and 8 ports. Besides, IO-Link is also perfectly embedded in ASi-5 and our user-friendly PC software – from the device to the PLC or cloud.

Versatile

drive solutions

Combine our ASi-5 and ASi-3 drive solutions to always have the perfect mix for any requirement. Our ASi-5 motor modules allow you to efficiently control 24 V and 48 V motorized rollers – from manufacturers such as Interroll, Itoh Denki and RULMECA, among others. As for frequency inverters, we offer solutions for SEW EURODRIVE, NORD, Lenze, Rockwell and Bonfiglioli, for example. ASi-5 is also an excellent solution for complex requirements in the drive sector.

Functional safety

for every system size

You can seamlessly integrate all the safety-related components required for packaging automation – safe sensors, actuators, and safety monitors – into your packaging automation system. Safe and standard signals can be transmitted on the same cable. This eliminates the duplication of infrastructure that was previously necessary.

Save valuable resources

With AS-Interface, you do not need expensive plugs or sockets and only a single cable. This significantly reduces assembly times and material costs. In addition, valuable resources such as copper or plastic, which are required to manufacture the components, can be saved on a large scale. And energy consumption during cable production is greatly reduced. There is also a positive environmental effect when it comes to disposal – less waste is produced.

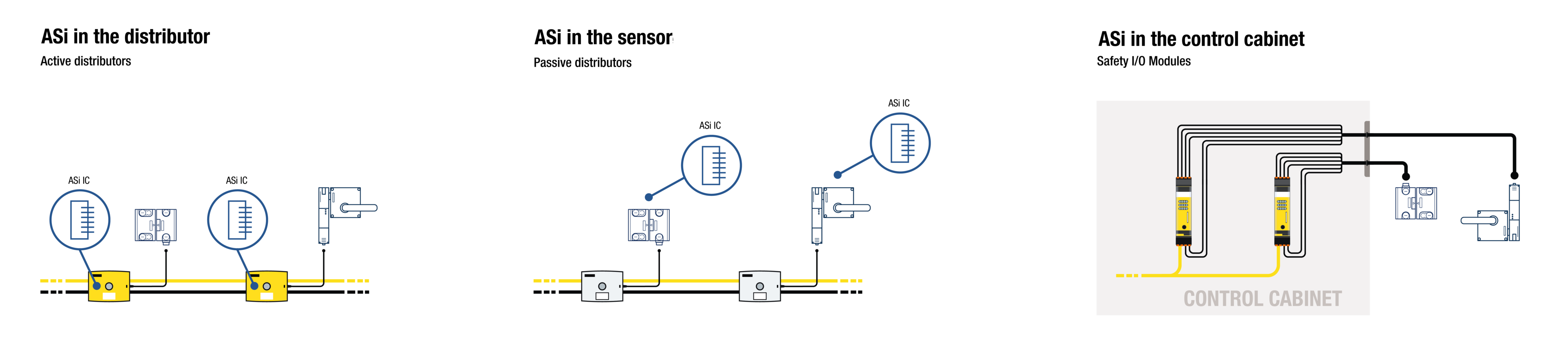

Easy integration of safety switches and door locks in ASi

Bihl+Wiedemann has developed active distributors ASi Safety with integrated ASi chip especially for safety switches from manufacturers, such as Schmersal, Pilz, Keyence and EUCHNER. They enable you to easily integrate safety switches from these manufacturers into ASi. The pin assignment matches the respective connection seamlessly (e.g., 8-pole M12 plug). This makes it very easy to integrate the devices into the ASi network.

Passive distributors enable ASi-capable components with an integrated ASi chip to be easily integrated into the installation system.

The particularly compact design of the active distributors and passive distributors has been optimized for the cable duct and opens up the possibility for completely individual installation paths. And thanks to pre-assembled cables, you not only save hardware costs and connection time, but also minimize potential sources of error. We are happy to develop additional variants upon request.

Of course, it is also possible to use conventional wiring in the control cabinet using our safety I/O modules in IP20.

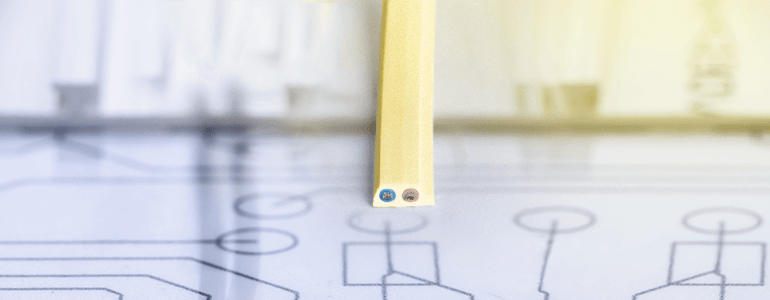

Data and power on one cable

ASi connects the modules in the lowest process level in automation systems with each other. The usual cable harnesses are replaced by a single electrical cable – the ASi cable. Both data and power are transmitted on this one cable.

Safety Basic Monitor

For small applications with three or more safe signals, we offer the Safety Basic Monitor, a safe small control without gateway, but with configurable signal outputs. The ASi Safety Module is universally expandable and is also suitable as a head station for special safety applications.

Cost-effective variant for small applications

Safe small control

Wide function range

Easily expandable via AS-Interface

Easy to integrate into existing systems

Simple coupling to other systems

Programmable via PC

Max. 31 safe modules per device

Narrow width Safety Basic Monitor: 22.5 mm

Products and solutions for packaging automation

Bihl+Wiedemann offers a wide range of solutions for packaging automation.

IO-Link Master

With the ASi modules with integrated IO-Link masters from Bihl+Wiedemann intelligent IO-Link sensors and actuators can now be easily incorporated into ASi – exactly there, where they are needed. The IO-Link sensors can be easily parametrized using the configuration tool from Bihl+Wiedemann

Drive solutions

ASi makes full use of all its strengths in material handling technology. The motor modules for roller drives from Bihl+Wiedemann allow 24V motors to be controlled directly through ASi without the need for an additional control device. The speed of any driven roller can be varied from a central location. Our modules also make it possible to make use of the braking energy of the rollers in the system. Inputs on the modules are used to read in signals from sensors installed along the conveyor line.

In addition to motor modules for roller drives, Bihl+Wiedemann also provides drive solutions for remotely controlling AC motors (with or without frequency inverters) – an essential prerequisite for implementing new system structures.

Safety components

In addition to the efficient transmission of standard data from the field to the controller/PLC, ASi safety at Work technology makes it possible to send safe signals up to PLe over the same 2-conductor ASi cable. This means safe I/Os can be checked and turned off right where the signal originates. The transmission of safe and non-safe signals over a single two-conductor cable immensely minimizes wiring while further optimizing the network layout.

![[Translate to Englisch:] Sicherheitskomponenten [Translate to Englisch:] Sicherheitskomponenten](/fileadmin/_processed_/f/c/csm_Produkte_Sicherheitskomponenten_a1e8ea3375.jpg)