Process technology with ASi – better performance, lower costs

What are the advantages of using AS-Interface (ASi) for process technology? Do you want to drastically reduce your wiring costs, integrate a wide range of IO-Link devices cost-effectively, or implement Industry 4.0 projects quickly and easily?

ASi – which supports all common fieldbus systems – also enables you to meet important documentation requirements, implement functional safety very economically, significantly increase system performance, save valuable resources, and avoid expensive connectors.

You also benefit from a wide range of ASi-5 valves, powerful modules for a wide variety of applications, and user-friendly software.

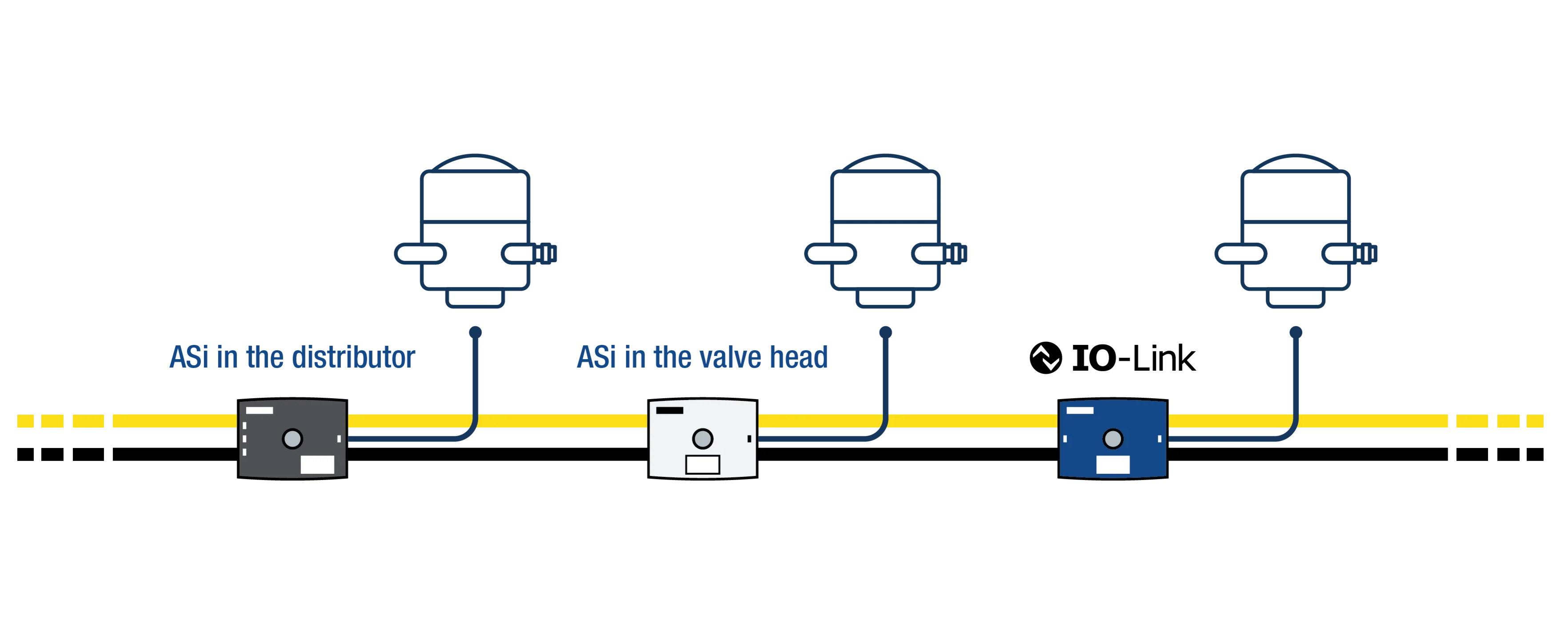

Fig.: With AS-Interface, the valves can be placed anywhere along the ASi cable. The above integration options are available.

How you benefit from ASi in process technology

- Many ASi-5 valves – e.g., from GEMÜ, SPX FLOW, or Sitomatic. These provide numerous additional diagnostic functions and parameters for process data, so that your system is optimally equipped for Industry 4.0.

- Cost savings with ASi-5 – The range of functions of the valve heads with integrated ASi-5 is comparable to that of the respective IO-Link solutions. However, you will not need to use any additional master ports or IO-Link communication.

- Modules for diverse tasks – A wide range of modules enables the simple integration of digital and analog inputs and outputs, IO-Link sensors, or serial protocols, such as RS232.

- Cost-effective functional safety – with ASi it is possible to integrate safety technology on the same line. Reliable monitoring of analog signals such as temperature, pressure, or fill level can thus be implemented easily and cost-effectively.

- Equipped for Industry 4.0 – ASi-5 provides detailed diagnostics and many parameterization options. Additional information can be read out at the same time as process data. ASi-5/ASi-3 gateways have interfaces such as OPC UA or REST API and can be integrated into FIM thanks to FIMlet. The interfaces also enable an IIoT connection and thus the recording and logging of parameter changes. This ensures that important documentation obligations are met.

Further questions about our products and solutions?

We would be happy to assist you.